Table of Contents

EV Battery Recycling Process

The sustainable action is the need of the hour. The world is shifting towards electric vehicles to combat climate change because the transportation sector plays a major role in greenhouse gas emissions.

EV Batteries are the heart of EVs, so it is also important for us to make EV battery production sustainable. By taking this action, we can reduce the exploitation of core minerals for lithium ion batteries.

The best solution is a lithium ion battery recycling process to meet the surge in demand for lithium ion batteries and to avoid mineral exploitation. This blog post by Renovar takes you through how to recycle lithium ion batteries.

Essential Terminology

Before beginning to understand the recycling process of lithium ion batteries, we must go through the basic terminologies related to lithium battery recycling.

| Terminology | Brief Description |

|---|---|

| Recycling | recycling is the process of transforming used batteries into valuable materials again, reducing waste. |

| Recovery Rate | Percentage of materials successfully extracted from used batteries. |

| Battery Pack | Housing multiple cells connected to store & deliver electrical energy. |

| Module | Smaller unit within a pack containing several interconnected cells. |

| Cell | The fundamental unit of a battery, storing & converting chemical energy to electricity. |

| Black Mass | A mixture of valuable metals (Li, Co, Ni) recovered from battery processing. |

| Anode | Negative electrode in a cell, attracting Li ions during discharge. |

| Cathode | Positive electrode, accepting Li ions during discharge and releasing them during charge. |

| Binder Agent | Glue-like material holding active materials in electrodes together. |

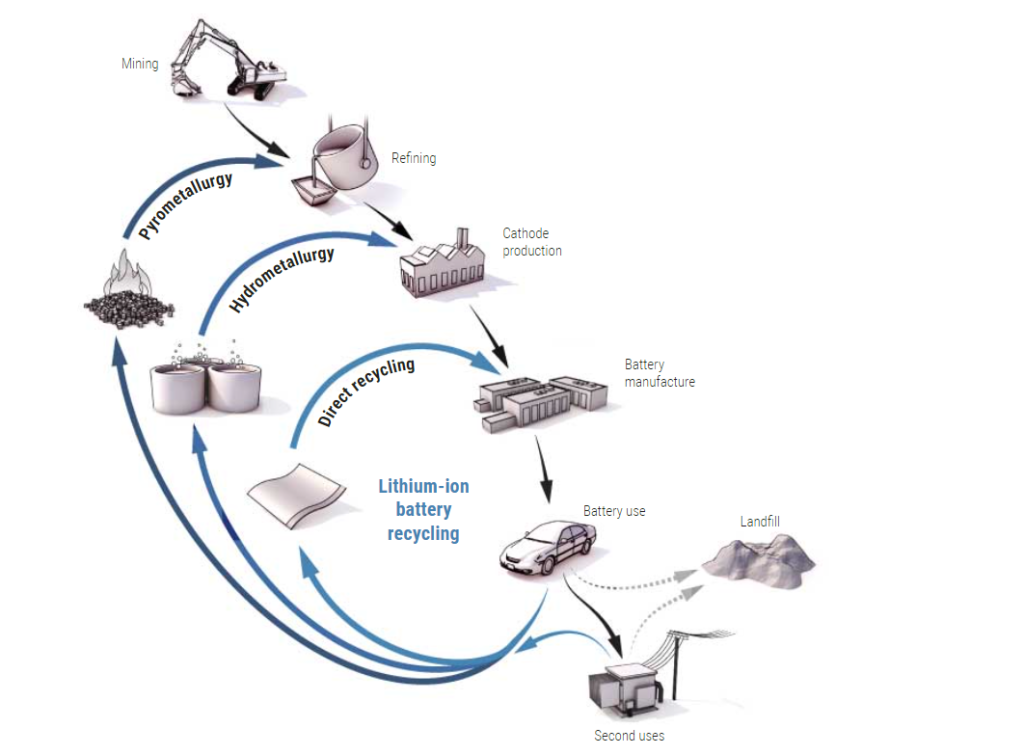

Types of EV Battery Recycling Process

There are three types of li ion battery recycling currently. We will discuss each in the following order.

- Direct Recycling

- Hydrometallurgy

- Pyrometallurgy

Source: Science

Direct Recycling

Recovering battery components directly without breaking down their chemical structure. This method is mostly employed in the recycling lithium-ion batteries. This method is less explored when compared to hydro and pyro metallurgy techniques.

It is also called direct cathode recycling & cathode-to-cathode recycling.

Pre-processing

Collecting used lithium ion batteries for recycling

Transporting them to a lithium battery recycling plant

Disassembling the batteries using a shredding machine for further processing

Separation Process

A feedstock of anode and cathode on current collectors is generated, consisting of valuable components like black mass, cu foil, electrolyte and Al foils. These processes utilise various material properties such as density, conductivity & solubility for efficient recovery.

Methods such us ethylene glycol delamination, froth flotation for cathode separation and novel approaches for binder removal and recovery.

Relithiation & Upcycling

The relithiation process restores lithium lost during battery cycling, with various methods under evaluation for efficiency and cost-effectiveness.

Upcycling transforms chemically outdated cathode materials to meet current battery formulation demands.

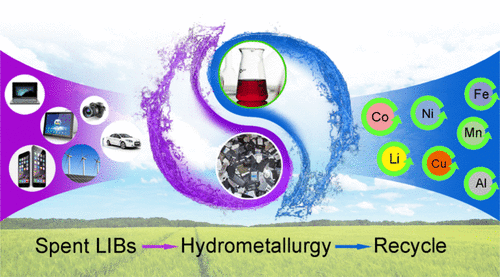

Hydrometallurgy

This technique uses liquid & chemical-based solutions to dissolve the battery materials and recover core minerals from the black mass.

Source: ACS

Pre-processing

- EV batteries are sent to recyclers for dismantling into modules

- Modules or cells are mechanically shredded into small pieces for separation

- Separation methods extract lithium, cobalt & nickel, forming a valuable black mass

Separation Process

Initially, electrodes are separated from the foil by chemical or thermal pre-treatment methods. The thermal process uses heat to eliminate glue and separate the electrodes, producing powder.

Leaching

This powder is then subjected to leaching, involving hydrogen peroxide and sulfuric acid, to dissolve minerals for further extraction. Then, the solvent extraction process separates valuable metals & isolates minerals from the dissolved solution.

The final output from hydrometallurgical recycling varies, ranging from a positive electrode precursor to individual materials like lithium, cobalt & nickel sulfate.

Pyrometallurgy

This conventional technique uses non-ferrous & valuable core minerals from electronic and EV batteries. Involves incineration, smelting in a furnace, sintering & melting at high temperatures.

Pre-processing

- Transportation of used lithium ion batteries from collection centres to recycling plant

- Dismantling & disassembling of EV batteries

Smelting

In this process, disassembled battery components are subjected to intense heat in a furnace, which causes the metals to melt and separate from non-metallic materials. The molten metal is then collected & solidified for further processing.

Smelting in battery recycling results in the loss of lithium, aluminium, and manganese in the slag. Cobalt and nickel recovery requires a subsequent hydrometallurgical process.

A notable portion of lithium is lost as dust, but an additional hydrometallurgical process can recover it.

Comparison Chart

| Performance Metrics | Direct Recycling | Hydrometallurgy | Pyrometallurgy |

|---|---|---|---|

| Recovery Rates | 90 to 99% of Ni, Li, Co & Mn | 90% of Ni & Co, 50% of Li | Ni & Co, 0% if Li |

| Negative Environmental Impact | Lower | Low | High |

| Mineral Quality | High | Medium | Low |

| Suitability | Lower Value Batteries | Batteries with Ni & Co | NiCd & NiMH |

Way Forward

As the EV industry grows, also the need for efficient and sustainable battery recycling methods increases. Each of the three methods discussed above has its pros & cons, and the best approach may be to use a combination of techniques depending on the specific battery.

Renovar, the battery recycling company, can ensure your EV batteries are recycled while reducing their negative environmental impact and maximising their resource potential. Reach out to us!

FAQ

How to recycle lithium batteries?

You can recycle lithium batteries by taking them to designated battery recycling centres/electronic waste recycling facilities or Call Renovar!

Can lithium ion batteries be recycled?

Yes, lithium ion batteries can be recycled. Many recycling centres accept them for proper disposal and recovery of valuable materials.

What is the battery disposal process?

The battery disposal process typically involves collecting used batteries, sorting them by type and then recycling them through various techniques to recover valuable materials.

How to dispose of lithium ion batteries?

To dispose of lithium ion batteries properly, take them to a designated battery recycling facility or drop-off location to ensure safe and environmentally friendly disposal.

What are ion techniques in battery recycling?

Ion techniques are methods used in battery recycling plants to extract valuable materials like lithium, cobalt and nickel from lithium ion batteries.

Are there battery recycling companies?

Yes, there are many battery recycling companies that specialize in collecting, processing and recycling various types of batteries, including lithium ion batteries.