We all have to accept the fact that there won’t be any reduction in the usage of electronics in the far future. As time progresses, there will be a tremendous increase in electric vehicles worldwide.

As the main power source of electronics and EVs, demand for Lithium-ion batteries will drastically increase. Additionally, improper disposal of used Li-ion batteries harms the environment and human health. Also, fire hazards and battery explosions are possible.

To meet the demand and to avoid any environmental contamination, the Lithium-ion battery recycling plant is of paramount importance. Recycling is a crucial tool to reduce the need for lithium-ion mineral exploitation from mining significantly.

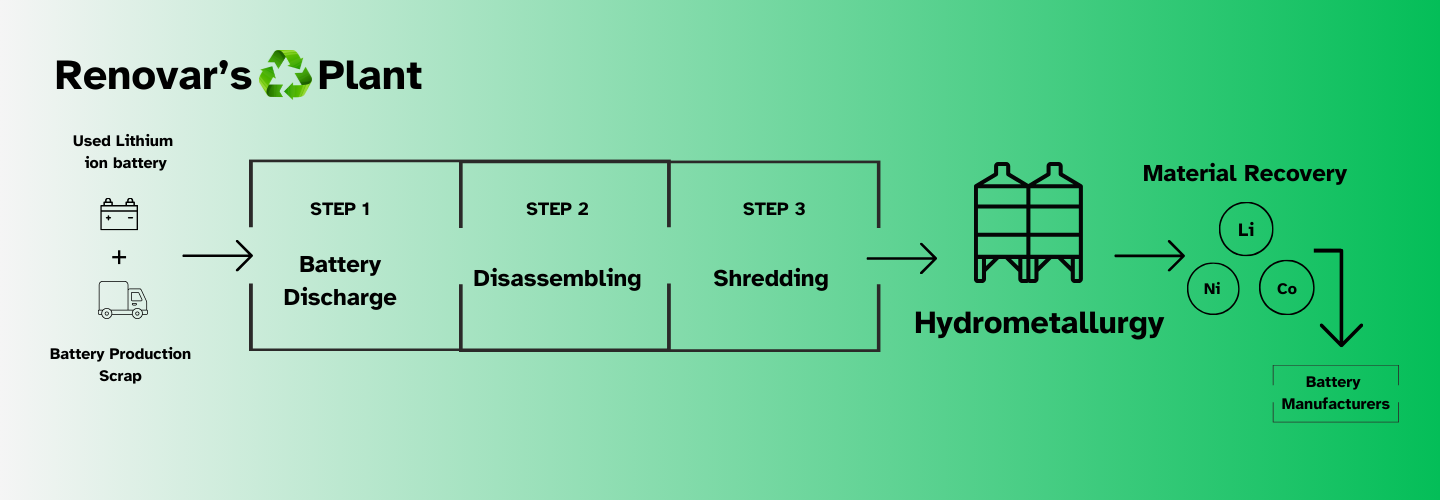

As Renovar being the one of the best lithium ion battery recycling companies in India, we employ hydrometallurgy technique for recycling process of lithium ion batteries. It is more eco-friendly and efficient than pyrometallurgy process.

For lithium battery recycling in India or anywhere around the world, pre-processing stage is inevitable. In order to employ hydrometallurgy it is necessary to go through these following processes.

Li ion battery scrap/scrap lithium batteries are directly procured from battery manufacturing companies. And battery wastes from battery disposal are collected from used lithium ion battery dealers and dismantlers. For partnering with us, click here.

Discharging batteries before processing enhances safety, minimizing the risk of fire hazards. It ensures a safer work environment, improves efficiency, enhances metal recovery rates and reduces the environmental impact of recycling.

Disassembling large lithium-ion batteries before hydrometallurgy enhances shredding efficiency and material accessibility. It enables better separation of valuable metals, such as electrodes and casings, leading to individual recycling and potentially higher purity of recovered materials.

Breaking down batteries using a mechanical shredder increases the surface area for chemical reactions. It enables the separation of black mass, optimizing processing for improved recovery rates and safety.

As one of the leading technologies for recycling used lithium-ion batteries, it offers several advantages over other methods. Thus making it a valuable tool for addressing the growing challenge of used battery management.

In the leaching stage, the black mass undergoes treatment with acidic or alkaline solutions, dissolving valuable metals such as lithium, cobalt, nickel and manganese. Subsequent separation techniques isolate individual metals, including precipitation, ion exchange and solvent extraction.

Extracted metals then undergo purification and refining processes to meet stringent industry standards.

We achieve an impressive 95% recovery of vital battery metals, ensuring a sustainable source of raw materials, including Lithium (Li), Cobalt (Co), Nickel (Ni) and Manganese (Mn).

Call Renovar or contact authorized battery recyclers in your area for proper disposal.

Take used batteries to designated collection points, electronic retailers or battery recycling programs to ensure safe and environmentally friendly disposal.

Yes, lithium-ion batteries can be recycled. Utilize dedicated battery recycling services to properly dispose of and recover valuable materials.

Drop off used batteries at designated recycling centres, follow local guidelines, or contact recycling facilities for safe and responsible disposal.

Safely dispose of lithium-ion batteries by utilizing battery drop-off points, electronic waste recycling programs or contacting authorized recyclers for proper handling.

Contact Renovar through our app or locate nearby battery recycling centres through online directories, contact local waste management authorities.